HORA eTec keeps connections permanent in electrical engineering.

From prototype production to pilot runs to series production kick-off, whether simple, complex or finished components.

For a Permanent Connection

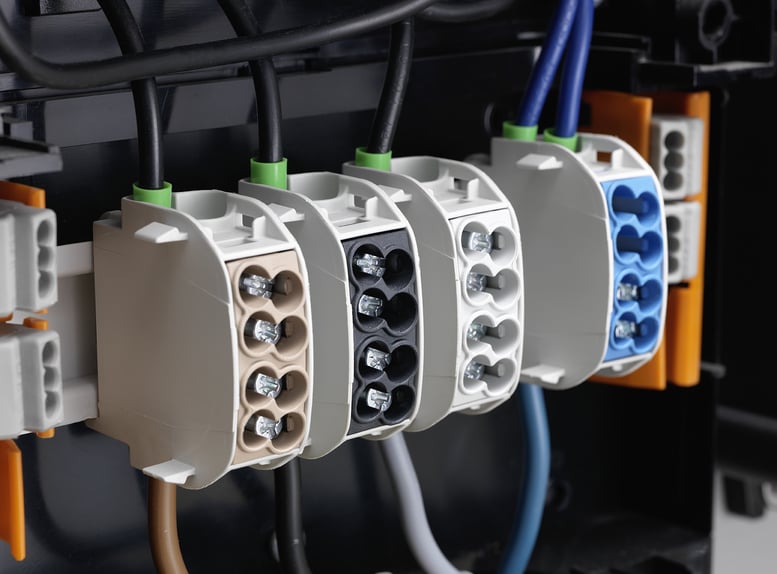

Aluminium Terminal Blocks:

Large cross-sections for a variety of applications

Terminal blocks compatible with aluminium and copper conductors

Unlike other product families from HORA eTec, these terminal blocks have aluminium bodies. A special coating ensures that the terminals are not only suitable for aluminium conductors, but also copper conductors. HORA eTec terminal blocks have worldwide approval for conductors in either material. An added benefit can be found in the substantially lower weight of HORA eTec terminal blocks due to the aluminium body, compared to more conventional terminal blocks.

The HORA eTec RKA series of aluminium terminal blocks covers a wide variety of applications. Mechanical engineering, industrial equipment, automation, wind turbines, solar energy or other electrical engineering switchgear – HORA eTec terminal blocks are a highly versatile solution. A multitude of features presents major benefits in connection technology. All HORA eTec aluminium terminal blocks are of course finger-safe on all sides according to DIN EN 50274.

HORA eTec has focused on relatively large cross-sections to make it far easier to connect large cables; conductor cross-sections of up to 300 mm² are supported in various versions.

The range includes a variety of terminal blocks:

• RKA 50 (50 mm²)

• RKA 95 (95 mm²)

• RKA 185 (185 mm²)

• RKA 300 (300 mm²)

Terminal blocks with large cross-sections for various conductor shapes

There is a certain reason for these relatively large cross-sections: whether round or sector-shaped, solid, stranded or flexible conductors, the added space allows all these cables to be installed. HORA eTec terminal blocks not only allow conductor connections, but are also perfectly capable of power distribution.

The HORA eTec RKA series is very user-friendly mainly due to the compact, space-saving and robust nature of these terminal blocks. All types can be mounted on mounting plates or TS 35 rails according to IEC 60715 / DIN EN 50022.

All terminal blocks have push-through protection through-out to keep conductors from touching in the middle, and possibly oxidising. The screws have hex heads allowing the constant high torque required while installing the conductors using an Allen key. The turned screw ends prevent damage to the relatively soft aluminium conductor material on installation. The body and the plastic housing are designed to ensure effective heat dissipation while in use.

Distribution Blocks:

Power distribution with large cross-sections made easy

Distribution blocks suitable for connecting flat,

round and sector-shaped solid, stranded or flexible conductors

Distribution blocks face increasing requirements. Power in plant and machinery often needs to be distributed to additional consumers such as motors – as efficiently as possible, of course. Conductor cross-sections of increasing sizes with minimum space requirements have placed the focus squarely on distribution blocks for users.

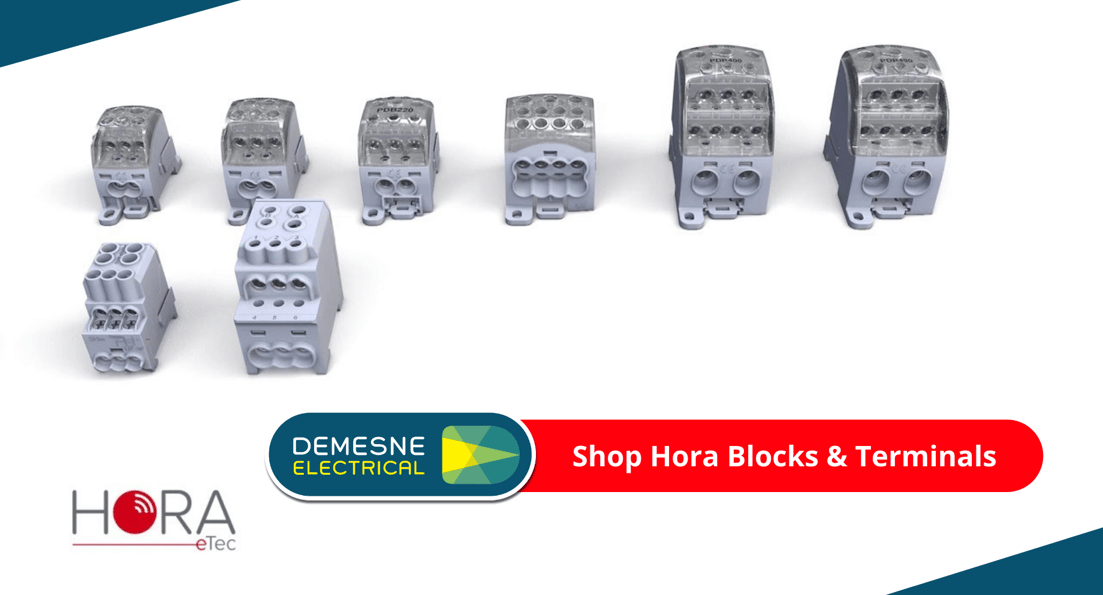

The PDB series of distribution blocks from HORA eTec benefits from a high degree of user-friendliness, cost efficiency and safety, providing an ideal solution wherever power is supplied and distributed through conductors with relatively large cross-sections. Every version in the series has approval for connection to aluminium or copper conductors thanks to a specialised coating on the brass body throughout the component.

Step design in distribution blocks to make conductor insertion visible

The design ensures excellent user-friendliness in HORA eTec distribution blocks. The step design in the brass body leaves conductor insertion in clear view at all times through a transparent cover. This makes assembly of the distribution blocks easy and safe while wiring up the terminals. Users already save costs due to the optimized design. The simplified screw assembly saves significant amounts of time.

There are no torque losses during assembly as brake screws are not needed. Special chambers prevent loss of screws in the plastic casing. Whether quick mounting on a TS 35 rail according to IEC 60715 / DIN EN 50022 or directly screwed onto the mounting plate, HORA eTec distribution blocks are always easy and versatile to install.

All HORA eTec distribution blocks are ideal for connecting round or flat conductors. The outputs feature a large number of smaller terminals for further power distribution. Apart from that, extending the number of outputs is easy and safe as the distribution blocks can be stacked and extended to any requirement using phase rails for smaller distribution blocks and pre-assembled flat copper bridges as accessories for larger ones.

These accessories even make it possible to triple the number of outputs, allowing further power distribution from one input to large numbers of additional conductors instead of installing new supply lines. All distribution blocks can be combined freely with one another in a modular approach making it very easy to construct multipolar systems.

The HORA eTec distribution block range comprises six different versions:

• PDB 160 (160A)

• PDB 210 (210A)

• PDB 220 (220A)

• PDB 270 (270A)

• PDB 400 (400A)

• PDB 490 (490A)

Distribution blocks designed to meet increasing safety requirements

All versions are finger-safe on all sides according to DIN EN 50274, and also feature short-circuit resistance according to the exacting SCCR standard to add to the high level of safety. This means that HORA eTec distribution blocks meet current and constantly increasing safety requirements on terminal technology. Distribution blocks for neutral conductors are equipped with transparent blue covers. The plastic casing also includes individual connection labels. The ergonomic design with rounded edges as goods as eliminates the risk of injury during assembly.

HORA eTec distribution blocks are approved worldwide according to VDE, UL, CSA, FI and EAC. The plastic casings are self-extinguishing and halogen-free. HORA eTec provides custom brand labelling and delivery in customised industrial packaging.

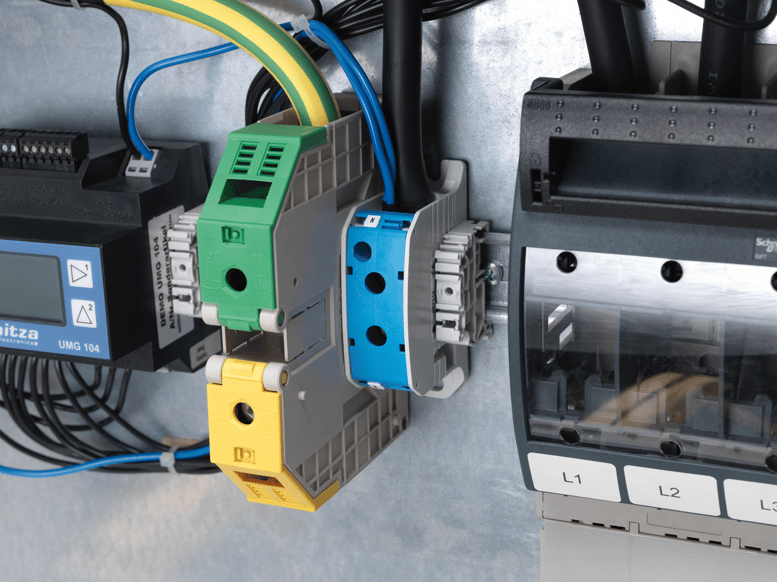

Main Line Branch Terminals:

Cost efficiency, simplicity and safety

Main line branch terminals in optimised design

Main line branch terminals are the first choice for connecting mains supply conductors. HORA eTec components are also suitable for use in other application areas, such as junction boxes. Main line branch terminals feature an optimized design, with the HORA eTec range covering both A and part-safe B designs as well as C designs that are finger-safe on all sides. These last designs have since come to dominate the field in electrical engineering solutions.

HORA eTec main line branch terminals benefit from huge savings in costs due to the optimized design in the brass body, and simplified screw mounting cuts installation times. Dome technology keeps screws attached to the plastic casing, preventing loss. No brake screws are needed, eliminating torque loss during installation. The rounded edges ensure a user-friendly design.

The plastic casings are self-extinguishing and halogen-free. Identical design in every 25 mm² and 35 mm² main line branch terminal ensures free stacking and combination arrangements. All main line branch terminals can be horizontally and, in most cases, vertically mounted on TS 35 rails according to IEC 60715 / DIN EN 50022. The mature technology used is suitable for voltages up to 1.000V AC or DC.

Main line branch terminals in various designs

Our range covers the following C versions::

• 25 mm² main branch terminal: single pole, single or double block; three, four or five poles

• 35 mm² main branch terminal: single pole, single or double block; three, four or five poles

• 70 mm² main branch terminal: single pole

The entire main line branch terminal range has been certified and approved according to IEC, VDE, UL, CSA and FI. All versions have also been subjected to independent power-loss testing at SGS Fimko. All C-versions of the HORA eTec main line branch terminals are approved for round or sector-shaped solid, stranded and flexible conductors in copper or aluminium; a specialised triple coating on the brass body makes this possible.

25 mm² version available in MCB width

HORA eTec main line branch terminals are currently the narrowest on the market. The module width of 17.8 mm on 25 mm² main branch terminals saves lots of space and therefore huge costs. HORA eTec will optionally custom-label your main line branch terminals with your customer brand on request. Delivery in custom industrial packaging is also available. All main line branch terminals fulfil the EC Directive on the Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS). Covers in the respective live, neutral, and earth colours are available.

Apart from the C-type models, HORA eTec supplies non-finger-proof A-type and the vertically finger-proof B-type main line branch terminals, each available in 25 mm², 35 mm²/25 mm² and 35 mm² versions. All the non-finger-safe main line branch terminals are available in single, double, four and five-pole versions.

HORA, Experts in Electrical Technology Since 1919

SHOP HORA BlOCKS & TERMINALS AT DEMESNE TODAY