Why Is Explosion Protection Needed?

An explosion is classed as an exothermic chemical reaction of a mix of inflammable gases, vapours, mists or dusts with air. The result is a rapid release of heat and subsequently a rise in pressure.

Explosion protection equipment is needed to help protect workers and property while mining & processing of hazardous raw materials.

e.g. potential hazardous gas, vapour & dust.

The need for effective ATEX electrical equipment is vital, when you consider some major incidents in recent years, such as an explosion at a Flixborough plant in the UK, where 30 tonnes of cyclohexame leaked resulting in a vapour cloud explosion, killing 28 people.

Also, in 2001, a large expolsion occured at a ammonium nitrate & fertilizer factory in Toulouse in France, killing 29 people.

Explosion protection equipment can be required in the following areas:

- chemical plants

- refineries

- offshore platforms

- food & beverage plants

- lumber mills

- pharma plants

Download your ATEX Product Guide here

Possible Ignition Sources

Assuming that a combustible material and oxygen is present, the following can be causes of explosions in the workplace:

Heat

- open flames

- hot gasses

- sunlight

- infrared heat

- friction heat

Electrical Spark

- switching contacts

- short circuits

- over voltage

- electrical discharges

Mechanical Spark

- friction

- hammering

- grinding

European 'Explosive Atmosphere' Legislation

Here in Europe, we have ATEX & IECEx legislation in place to help protect workers in plants where explosions are a possibility.

Directive ATEX 94/9/EC (ATEX95)

This directive became available for use in March 1996 and mandatory on July 1st 2003 and relates to harmonisation of the laws of EU member states concerning equipment and protective systems intended for use in potentially explosive atmospheres.

IECEx Scheme

This scheme is an international conform evaluation process for electrical equipment for use in potentially explosive atmospheres based on the IEC standards.

The IECEx scheme is now well adopted worldwide.

The IECEx run an online certification system , that can be viewed here - www.iecex.com

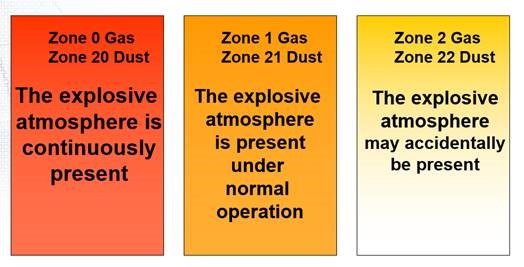

Zone Classification for Explosive Environments

Zone 0 (gas) / 20 (dust)

A place in which an explosive atmosphere (either consisting of a mixture with air of dangerous substances in the form of dust, gas, vapour or mist) is present continiously, or for long periods or frequently.

Zone 1 (gas) / 21 (dust)

A place in which an explosive atmosphere (either consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist) or (in the form of a cloud of dust in air) is likely to occur in normal operation occassionally.

Zone 2 (gas) / 22 (dust)

A place in which an explosive atmosphere (either consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist) r (in the form of a cloud of dust in air) is not likely to occur in normal operation, but , if it does occur will persist for a short period only.

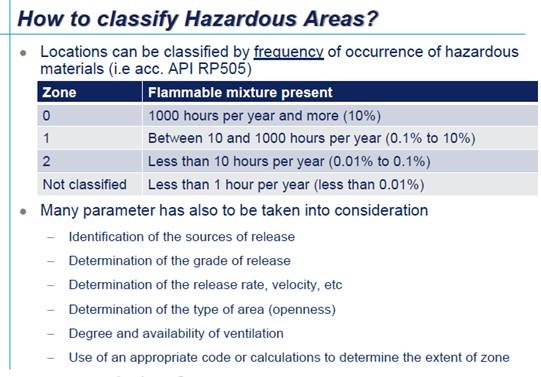

How to Classify Hazardous Areas

Electrical Equipment for Explosive Atmospheres - Emerson Product Guide

The Emerson ATEX Product Guide gives information on their vast range of ATEX certified products including lighting, enclosures & industrial plugs & sockets, as well as extra information on zone classifications for specific industries.

Download Your Copy Here